From pixel to printed poster

Screen printing is a technique that dates back to the Chinese Song Dynasty (960–1279) AD. However, the process only became popular in Europe during the 18th Century when we gained access to the relevant materials. Traditionally achieved by hand using a silk mesh, printing can now processed on a mass scale using man-made materials (we use Swiss and Italian polyester mesh) and highly complex machinery.

Screen printing is a faster and cheaper printing method than digital printing as it can be achieved using singular or dual inks. Even if a poster composing of only one or two colours was printed digitally, the printer would still use a mix of all the colours available, whereas the screenprinter uses pure forms of ink.

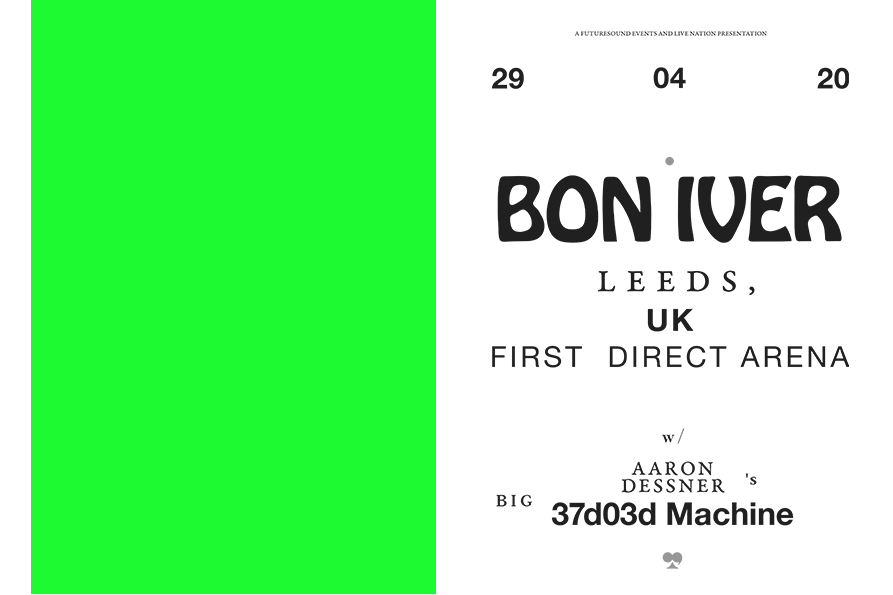

Upon receiving artwork from one of our clients – for example here we have Futuresound’s event – Bon Iver with 37s03d Machine at Leeds First Direct Arena – the artwork is checked thoroughly and separations made where appropriate. It is converted into a Halftone or Bitmap image. A halftone image is comprised of discrete dots rather than continuous tones. When viewed from a distance, the dots blur together, creating the illusion of continuous lines and shapes, as can be seen if you zoom in on the image below.

By halftoning an image (converting it from a bitmap to a halftone), it can be printed using less ink – again helping to cut down on costs.

The Bon Iver poster was a dual colour job with the background being a fluorescent green (eyecatching!) and the text 100% black.

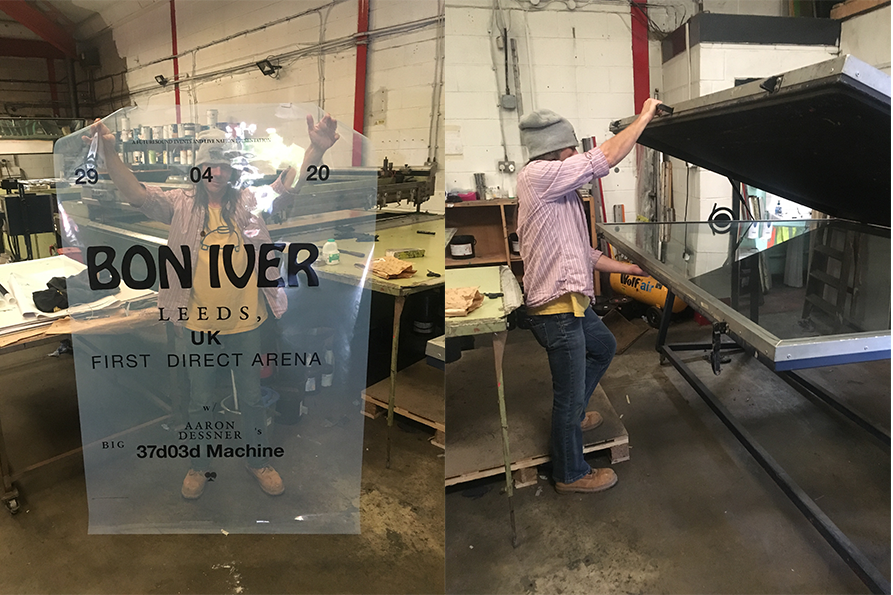

The screen is emulsion-coated in a dark room. Then the screen is washed with a pressure washer. Where the black is, there is now a hole to allow the ink to get through. The film is exposed onto the screen using a UV Lightbox. Then the screen and frame are lined up with invisible tape and pre-pressed with a vacuum to block out any pin holes in the emulsion which would create imperfections in the print.

Here at Pop Art we use a 60×40 semi-automatic screen printing press. The screen is placed atop a substrate and the ink is placed on top of the screen. A floodbar is used to push the ink through the holes.

The prints are then left to dry and posted around Leeds by our team of fitters on our billboards and poster drums.